Product Description

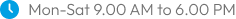

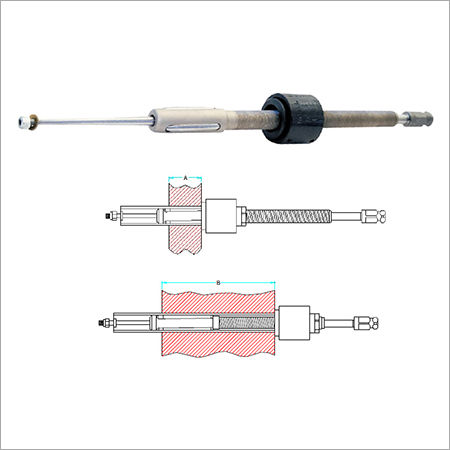

Evaporator Tube Expander

Tube Internal diameter : 8.4mm (0.334) to 36.3mm (1.43)

Roller Length of Tube Expander : 1.1/2 (38.1mm) & 2.1/4 (57.1mm)

Sizes Available : 1/2 O.D. to 1.1/2 O.D.

FEATURES :

Use : This is recommended for heat exchanger & condenser with tubes of 5/8- 1.1/2 O.D. & thick tube sheets.

Technical Specification

| Tube Expanders fitted with roller length | For Tube sheet adjustable range |

| Minimum A | Maximum B |

| (38.1 mm) 1.1/2'' | STD. Reach | (38.1mm) 1.1/2'' | (152.4mm) 6'' |

| ''A'' Reach | (38.1mm) 1.1/2'' | (203.2mm) 8'' |

| ''B'' Reach | (38.1mm) 1.1/2'' | (253.8mm) 10'' |

| ''C'' Reach | (38.1mm) 1.1/2'' | (304.6mm) 12'' |

| ''D'' Reach | (38.1mm) 1.1/2'' | (355.6mm) 14'' |

| (57.1mm) 2.1/4'' | STD. Reach | (57.1mm) 2.1/4'' | (171.4mm) 6.3/4'' |

| ''A'' Reach | (57.1mm) 2.1/4'' | (222.1mm) 8.3/4'' |

| ''B'' Reach | (57.1mm) 2.1/4'' | (272.8mm) 10.3/4'' |

| ''C'' Reach | (57.1mm) 2.1/4'' | (323.6mm) 12.3/4'' |

| ''D'' Reach | (57.1mm) 2.1/4'' | (374.6mm) 14.3/4'' |

| Tube O.D. (mm) inch | Tube Thickness | Tube I.D. | Minimum I.D. Tool Enters | Maximum Expansion of Tool | Expander with (38.10mm) 1.1/2'' Long rollers | Expander with (57.15mm) 2.1/4'' Long rollers | Ratchet size |

| Bwg | Inch | mm | Inch | mm | Inch | mm | Inch | mm | Complete Tool No. | Roller Set No. | Mandrel No. | Complete Tool No. | Roller Set No. | Mandrel No. | Square Inch |

| (12.70) 1./2 | 14 | .83 | 2.10 | .334 | 8.4 | .324 | 8.2 | .374 | 9.5 | B1197 | 797 | 1197 | - | - | - | 3/8 |

| 15 | .72 | 1.82 | .356 | 9.0 | .348 | 8.8 | .398 | 10.1 | B1199 | R-1 | 1199 | - | - | - |

| 16 | .65 | 1.65 | .370 | 9.4 | .360 | 9.2 | .410 | 10.4 | B1201 | R-1 | M-51 | - | - | - |

| 17 | 0.58 | 1.47 | .384 | 9.7 | .374 | 9.5 | .424 | 10.7 | B1203 | R-2 | M-51 | - | - | - | 3/8 |

| 18 | 0.49 | 1.24 | .402 | 10.2 | .392 | 9.9 | .447 | 11.3 | B1205 | R-3 | M-52 | - | - | - |

| 20 | 0.35 | 0.88 | .430 | 10.9 | .406 | 10.3 | .461 | 11.7 | B1205 S | R-3 | M-53 | - | - | - |

| (15.88) 5./8 | 12 | .109 | 2.76 | .407 | 10.3 | .392 | 9.9 | .447 | 11.3 | B1205 | R-3 | M-52 | - | - | - | 3/8 |

| 13 | .095 | 2.41 | .435 | 11.0 | .425 | 10.8 | .480 | 12.1 | B1207 | R-4 | M-53 | - | - | - |

| 14 | .083 | 2.10 | .459 | 11.6 | .449 | 11.4 | .509 | 12.9 | B1209 | R-4 | M-54 | B1210 | R-4-A | M-54 |

| 15 | .072 | 1.82 | .481 | 12.2 | .471 | 11.9 | .536 | 13.6 | B1211 | R-5 | M-55 | B1212 | R-5-A | M-55 | 3/8 |

| 16 | .065 | 1.65 | .495 | 12.5 | .485 | 12.3 | .550 | 13.9 | B1213 | R-6 | M-55 | B1214 | R-6-A | M-55 |

| 17 | .058 | 1.47 | .509 | 12.9 | .499 | 12.6 | .564 | 14.3 | B1215 | R-6 | M-56 | B1216 | R-6-A | M-56 |

| 18 | .049 | 1.24 | .527 | 13.3 | .517 | 13.1 | .572 | 14.5 | B1217 | R-7 | M-57 | B1218 | R-7-A | M-57 |

| 19 | .042 | 1.06 | .541 | 13.7 | .522 | 13.2 | .582 | 14.7 | B1219 | R-7 | M-56 | B1220 | R-7-A | M-56 | 3/8 |

| 20 | .035 | 0.88 | .555 | 14.1 | .536 | 13.6 | .596 | 15.1 | B1219S | R-7 | M-58 | B1212 | R-7-A | M-58 |

| 21 | .032 | 0.81 | .561 | 14.2 | .536 | 13.6 | .596 | 15.1 | B1219S | R-7 | M-58 | B1216 | R-7-A | M-58 |

| 22 | .028 | 0.71 | .569 | 14.4 | .536 | 13.6 | .596 | 15.1 | B1219S | R-7 | M-58 | B1220 | R-7-A | M-58 |

Precision and Durability for Demanding ApplicationsBuilt from high-strength steel and precision-machined, the Evaporator Tube Expander stands out for its robust construction and lasting durability. Its corrosion-resistant finish preserves the tool even in challenging environments, making it exceptionally suited for industrial use in HVAC and heat exchange systems.

Ergonomic and Adjustable for User ComfortOperator fatigue is minimized thanks to the expanders ergonomic, non-slip grip handle. With an adjustable working length, the tool adapts to different tube depths, providing greater flexibility and control during manual operation.

Universal Compatibility and CustomizationThis manual tube expander works seamlessly with copper, brass, stainless steel, and carbon steel tubes. It also supports custom size requests, ensuring a tailored solution for varied tube expansion needs in numerous applications.

FAQs of Evaporator Tube Expander:

Q: How is the Evaporator Tube Expander operated during tube expansion?

A: The Evaporator Tube Expander is operated manually, utilizing a smooth roller expansion method. Its ergonomic, non-slip handle ensures comfortable use while providing the necessary leverage for controlled expansion within evaporators, condensers, chillers, and heat exchangers.

Q: What types of tube materials are compatible with this expander?

A: This tube expander is suitable for a wide array of materials, including copper, brass, stainless steel, and carbon steel. Its hardened steel rollers are engineered to handle these materials without compromising durability or performance.

Q: When would I need to adjust the working length of the tube expander?

A: Adjustment of the working length becomes necessary when dealing with tubes of varying depths within heat exchangers or similar equipment. This flexibility allows for precise expansion, regardless of tube depth or equipment configuration.

Q: Where can the Evaporator Tube Expander be effectively used?

A: The tool is ideal for use in applications requiring tube expansion inside evaporators, condensers, chillers, and heat exchangerstypically found in the HVAC and process industries.

Q: What is the process for requesting a custom size for specific tube dimensions?

A: To request a custom size, you should contact the manufacturer or supplier directly with your specific tube measurements and application requirements. Customized options ensure compatibility with unique or non-standard tube sizes.

Q: What benefits does the corrosion-resistant coating provide?

A: The corrosion-resistant coating protects the expander from rust and wear, ensuring longevity even in humid or chemically aggressive environments. This feature extends the service life and maintains performance over time.

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese