Product Description

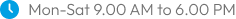

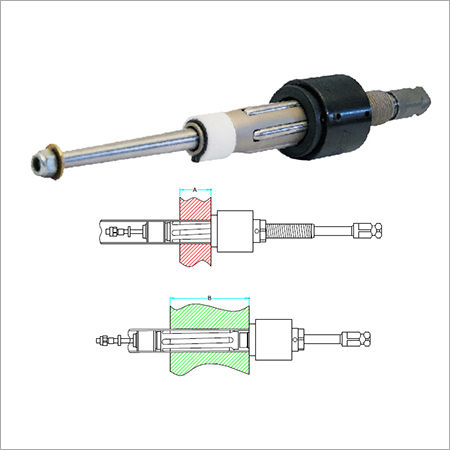

Condenser Tube Expander

- Sizes Available : 1/2 O.D. to 1.1/2 O.D.

- Tube Internal diameter : 8.4mm (0.334" ) to 36.3mm (1.43 )

- Roller Length of Tube Expander : 1.1/2 (38.1mm) & 2.1/4 " (57.1mm)

FEATURES :

Use- This is the most popular expander for use on heat exchanger and condensers with tubes of 1/2 - 1.1/2 O.D.

Technical Specification

| Tube Expanders fitted with roller length | For Tube sheet adjustable range |

| Minimum A | Maximum B |

| (38.1mm) 1.1/2'' | (12.7mm) 1/2'' | (38.1mm) 1.1/2'' |

| (57.1mm) 2.1/4'' | (31.7mm) 1.1/4'' | (57.1mm) 2.1/4'' |

| Tube O.D.

(mm) inch | Tube Thickness | Tube I.D. | Minimum I.D. Tool Enters | Maximum Expansion of Tool | Expander with (38.10mm) 1.1/2'' Long rollers | Expander with (57.15mm) 2.1/4'' Long rollers | Ratchet size |

| Bwg | Inch | mm | Inch | mm | Inch | mm | Inch | mm | Complete Tool No. | Roller Set No. | Mandrel No. | Complete Tool No. | Roller Set No. | Mandrel No. | Square Inch |

| (12.70) 1./2 | 14 | .83 | 2.10 | .334 | 8.4 | .324 | 8.2 | .374 | 9.5 | B797 | 797 | 797 | - | - | - | 3/8 |

| 15 | .72 | 1.82 | .356 | 9.0 | .348 | 8.8 | .398 | 10.1 | B799 | R-1 | 799 | - | - | - |

| 16 | .65 | 1.65 | .370 | 9.4 | .360 | 9.2 | .410 | 10.4 | B801 | R-1 | M-1 | - | - | - |

| 17 | 0.58 | 1.47 | .384 | 9.7 | .374 | 9.5 | .424 | 10.7 | B803 | R-2 | M-1 | - | - | - | 3/8 |

| 18 | 0.49 | 1.24 | .402 | 10.2 | .392 | 9.9 | .447 | 11.3 | B805 | R-3 | M-2 | - | - | - |

| 20 | 0.35 | 0.88 | .430 | 10.9 | .406 | 10.3 | .461 | 11.7 | B805 S | R-3 | M-3 | - | - | - |

| (15.88) 5./8 | 12 | .109 | 2.76 | .407 | 10.3 | .392 | 9.9 | .447 | 11.3 | B805 | R-3 | M-2 | B806 | R-3-A | M-2 | 3/8 |

| 13 | .095 | 2.41 | .435 | 11.0 | .425 | 10.8 | .480 | 12.1 | B807 | R-4 | M-3 | B808 | R-4-A | M-3 |

| 14 | .083 | 2.10 | .459 | 11.6 | .449 | 11.4 | .509 | 12.9 | B809 | R-4 | M-4 | B810 | R-4-A | M-4 |

| 15 | .072 | 1.82 | .481 | 12.2 | .471 | 11.9 | .536 | 13.6 | B811 | R-5 | M-5 | B812 | R-5-A | M-5 | 3/8 |

| 16 | .065 | 1.65 | .495 | 12.5 | .485 | 12.3 | .550 | 13.9 | B813 | R-6 | M-5 | B814 | R-6-A | M-5 |

| 17 | .058 | 1.47 | .509 | 12.9 | .499 | 12.6 | .564 | 14.3 | B815 | R-6 | M-6 | B816 | R-6-A | M-6 |

| 18 | .049 | 1.24 | .527 | 13.3 | .517 | 13.1 | .572 | 14.5 | B817 | R-7 | M-7 | B818 | R-7-A | M-7 |

| 19 | .042 | 1.06 | .541 | 13.7 | .522 | 13.2 | .582 | 14.7 | B819 | R-7 | M-6 | B820 | R-7-A | M-6 | 3/8 |

| 20 | .035 | 0.88 | .555 | 14.1 | .536 | 13.6 | .596 | 15.1 | B819S | R-7 | M-8 | B820S | R-7-A | M-8 |

| 21 | .032 | 0.81 | .561 | 14.2 | .536 | 13.6 | .596 | 15.1 | B819S | R-7 | M-8 | B820S | R-7-A | M-8 |

| 22 | .028 | 0.71 | .569 | 14.4 | .536 | 13.6 | .596 | 15.1 | B819S | R-7 | M-8 | B820S | R-7-A | M-8 |

Superior ConstructionPrecision-made using special alloy steel for the roll material, this device delivers excellent durability and reliable tube expansion over its extended lifetime. Its polished, corrosion-resistant surface further adds value by minimizing maintenance needs.

Versatile CompatibilityDesigned to accommodate copper, brass, and steel tubes, the Chiller Tube Expander addresses a wide range of heat exchanger and condenser requirements, making it a preferred tool for various industries.

Ergonomic and Efficient HandlingFeaturing an ergonomic handle, users benefit from firm grip and comfortable control, which supports accurate expansion and flaring processes. The choice of manual or pneumatic drive suits diverse operational environments.

FAQs of Chiller Tube Expander:

Q: How is the Chiller Tube Expander used in heat exchangers and condensers?

A: The Chiller Tube Expander is inserted into the tubes and then operated manually or pneumatically to expand and flare the tube ends, ensuring a tight fit and optimal thermal performance for heat exchangers and condensers.

Q: What materials are compatible with this expander tool?

A: This expander is suitable for copper, brass, and steel tubes, thanks to its robust alloy steel rolls which provide consistent and durable tube expansion across different materials.

Q: When should a chiller tube expander be utilized during maintenance or installation?

A: It should be employed when installing new tubes or during maintenance where existing tubes require re-expansion or flaring to prevent leakage and maintain efficient heat transfer in the system.

Q: Where can I obtain the Chiller Tube Expander in India?

A: The Chiller Tube Expander is available through reputable Indian exporters, manufacturers, and suppliers. It is typically supplied in a protective carry case for safe storage and transport.

Q: What is the process of expanding and flaring tubes with this tool?

A: The process involves placing the expander into the tube and either manually or pneumatically actuating the device. The special alloy rolls then expand and flare the tubes for a secure and leak-proof installation.

Q: How does the corrosion-resistant surface finish benefit users?

A: The corrosion-resistant and polished finish extends the tools lifespan, reduces wear, and ensures reliable operation even in demanding environments, minimizing the need for frequent replacements.

Q: What are the usage advantages of the ergonomic handle design?

A: The ergonomic handle provides a secure and comfortable grip, giving users greater control and precision during expansion, reducing operational fatigue and enhancing safety during use.

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese